Key Components Of A Mobile Asset Tracking Software

A mobile asset tracking system is built on several essential components that work together to deliver real-time visibility and control.

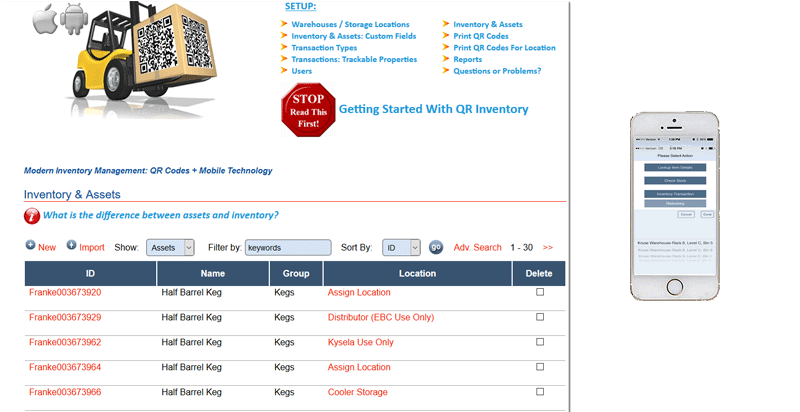

Mobile App

-

iOS and Android mobile apps allow for fast and easy real-time updates and live info access anywhere.

Smart Tags: QR Codes, Barcodes, NFC, BLE

-

Smart tags scanning with a smartphone replaces manual data entry for the fast and accurate asset identification and data capture.

Centralized Cloud Platform

-

Centralized cloud platform links all tracking devices into a unified system, allowing for real-time updates and access from smartphones, tablets, and office computers.

IoT Gateways & Sensors

- BLE tags, IoT sensors and gateways automate asset location tracking, condition monitoring, and misplacement alerts.

Core Features And Benefits Of Mobile Asset Tracking In The QR Inventory Software

QR Inventory software goes beyond asset location tracking with a smartphone and QR codes. QR Inventory system gives your team the tools

for efficient asset management, including location and usage tracking, job allocation, maintenance management, field reports, alerts

on important events and AI-powered analytical reports for better decision-making.

By combining a mobile app, smart tags, and a secure cloud backend,

QR Inventory software streamlines day-to-day business operations, while increasing data accuracy and accountability.

Top Mobile Asset Tracking Software Capabilities

- Real-Time Asset Tracking All asset movements and status changes: check out, rent, return, transfer between sites, sending to repair,

receiving or disposal are recorded on the spot, in real-time, using mobile app and QR code / barcode scanning.

- Streamlined Asset Check Out / Check In Field employees can easily record asset check out and return

with a QR code scan in a mobile app, note asset conditions, document them with photos and sign for checked out equipment.

This creates digital asset custody chain,

increasing employees' accountability and preventing tool and equipment misuse.

- Automated Asset Monitoring With BLE / IoT BLE / IoT system

automatically monitors asset location and status 24/7, without reliance on manual scanning with smartphones.

- Centralized Cloud Platform Centralized cloud platform links mobile devices and computers into one unified system, allowing for real-time updates and data access

for all team members.

- Mobile Forms For Asset Maintenance.

Field technicians can easily complete all types of paperwork, from asset maintenance to safety audits, on a smartphone using digital mobile forms.

- Alerts & Reminders Get automated alerts on critical asset info: asset misplacement using geofencing, maintenance expiration,

upcoming preventive maintenance, outliers in inspection form that require immediate action, low inventory of spare parts,

adverse temperature and humidity conditions, and more.

- Easy Customization Customize asset tracking process to your needs with custom workflows, data fields and properties,

custom mobile forms, customizable dashboards and reports, and more.

- AI / NLP Tools Simple software setup and daily use with AI / NLP tools.

Get answers to your asset management questions in seconds using natural language - no need to sift through instructions and manuals.

- Digital Records & Audit Trails.

Digital asset records are well organized, secure, accessible on demand from anywhere and are easily searchable.

Benefits Of Mobile Asset Tracking With QR Inventory Software

- Reduced Asset Loss And Theft Real-time asset monitoring and clear digital chain of custody improves accountability,

reducing asset damages, misplacement and loss.

- Improved Efficiency Automation of manual asset tracking processes saves businesses time and money,

and lets employees concentrate on core operational priorities.

- Better Asset Allocation And Planning Real-time asset visibility improves project scheduling and planning.

Companies can utilize assets to their maximum potential,

reducing purchase and rental costs.

- Timely Asset Maintenance Tools for monitoring and scheduling

equipment maintenance

and automated alerts ensure that preventive maintenance, routine inspections and calibration are not missed, preventing

unexpected breakdowns and increasing equipment lifespan.

- Permanent Digital Records

On demand access to accurate digital records helps businesses stay compliant with industry regulations and simplifies asset audits.

- Increased Safety Streamlined safety audits and digital documentation trail ensures that machinery and tools are safe to operate.

This reduces workplace accidents and can potentially lower company's insurance costs.

- Improves Decision-Making Accurate asset data, coupled with AI-based analytics to process it, helps businesses

with better purchases planning, improving asset utilization, optimizing inventory and forecasting asset and inventory needs.

- Increased Profitability Mobile asset tracking software helps businesses decrease operational costs,

reduce equipment loss and extend the life of valuable assets, increasing business profitability and ROI.

What QR Inventory Software Stands Out For In Mobile Asset Tracking

QR Inventory software is best for businesses who need to track all types of assets that are spread around multiple sites, assigned to employees,

are rented out or borrowed, and are frequently moved or re-assigned. It stands out for customizable workflows, wide selection of

asset tags and trackers to match your needs and budget, intuitive mobile app optimized for field work, and tracking automation with BLE/IoT.

Mobile Asset Tracking In QR Inventory Software At A Glance

QR Inventory Is Best For

QR Inventory software is best for field based businesses of all sizes who need to track tools, equipment, parts and materials

in multiple field and warehouse locations, want the system that is easy to use for field technicians,

customizable, flexible and scalable.

Key QR Inventory Features

Mobile App Functionality

- in app QR code / barcode / NFC / BLE scanning

- real-time asset transactions recording

- instant access to asset specs and documentation with the QR code scan

- custom equipment maintenance, calibration, inspection forms

- instant cloud sync

- capture of photos, signatures, GPS location

- custom pdf creation, printing, e-mailing

- easy navigation and use, optimized for field workflow

QR Inventory Differentiation

- Automated asset tracking with tags and devices that fit your needs and budget

- Highly customizable system with custom fields, forms, workflows and dashboards

- Optimized for field, multi-location asset tracking

- Modular design allowing companies to build asset management system that matches business requirements

- AI assistant makes

software setup and daily use easy and straightforward.

Why QR Inventory Software Is A Smart Choice For Field Asset Tracking

- Versatile Mobile App Optimized For Field Work

QR Inventory mobile app is intuitive, with easy navigation, minimal manual entries and plenty of options.

You can use it to look up asset info, check locations, spare parts stock and availability, record service and maintenance,

check past service records, and more. With QR code, NFC and BLE options, smart auto-fill, select hint lists, scannable checklist,

field employees can record assets transfer and service fast with minimal manual work.

- Customized Asset Tracking Process

Define your own asset tracking workflows and what you want to track, record and report via an intuitive web dashboard. Whether you need to

track tools and equipment between job sites, assign office assets to employees,

track what you have in rental properties, monitor hospital medical equipment - you can adjust asset management process to your use case and asset types.

- Asset Tracking Automation

Choose between tracking assets with the mobile app, or a fully automated tracking with BLE tags and IoT gateways.

Regardless of the method, centralized cloud database is updated in real-time, and you have full visibility into assets location and status from anywhere.

- Wide Selection Of Tags And Trackers

QR Inventory system has what works best for your workflow and budget. Choose cost-efficient QR code - mobile app tracking system,

NFC tags for faster scanning, bulk scanning using BLE tags and smartphones, or IoT system for a fully automated, hands-free asset tracking.

How Mobile Asset Tracking System Works, Step-By-Step

A mobile asset tracking system, such as QR Inventory, uses smartphones or tablets to scan and track assets

in the field, office and warehouses. Mobile devices update centralized cloud system in real time, giving the entire team life access to assets info, location, status and conditions.

Here is how you can use QR Inventory software for real-time mobile asset tracking, step-by-step.

1. Asset Tagging

- Each asset is labeled with a QR code, barcode, or BLE/NFC tag that uniquely identifies it.

- Easily link asset to its database record in the mobile app with a single scan.

- QR Inventory has built-in QR code generation and printing tool.

- In many cases you can use manufacturer barcodes if they are available.

2. Mobile Scanning

- Employees use a mobile app on their smartphone or tablet to quickly scan asset tags in the field or workplace.

- The scan uniquely identifies an asset, and fetches asset record from the central database.

- A record can include any info on the asset, including word descriptions, images, drawings and pdf documents.

- All this data are accessible by field, office and warehouse staff with a QR code scan.

3. Recording Asset Transactions

- Company employees record asset transaction in the mobile app.

- Transaction include everything that happens to the asset: transfer, assignment to an employee, check out and check in, service and maintenance records, and more.

- In the QR Inventory software, you can customize asset transactions, and define what data to collect for each transaction using custom fields and properties.

- Users can add photos to the transactions in the mobile app, and collect signatures on a smartphone for better accountability.

4. Real-Time Cloud Sync

- Asset location and status updates are sent from the mobile devices to the centralized cloud platform in real time.

- Cloud software updates asset data in the central database.

- Authorized software users can access live asset data from anywhere, on the mobile devices and office computers.

5. Data Review And Actionable Insights

- Real-time asset location, status, usage history, service records and other details are accessible from the cloud dashboard.

- Analytical, AI-powered reports sum up asset usage history, revealing patterns and trends.

This info helps businesses do better planning, improve asset utilization and optimize process for productivity and efficiency.

- Reports can be customized to show the exact info the company needs.

6. Alerts & Reminders

- The system provides alerts for low stock, misplaced or overdue assets, reported asset damages, and more.

How QR Inventory Mobile Asset Tracking Software Addresses Businesses' Pain Points

The QR Inventory mobile asset tracking system effectively addresses several common problems faced by businesses, including

lost and misplaced assets, lack of employee accountability for assets they borrow and use, inefficient tracking and maintenance, and poor asset utilization.

By providing real-time asset tracking with mobile scanning or IoT, and live data access through a centralized cloud platform it creates

accurate digital records and collects valuable data that help managers to make better, data-driven decisions.

Eliminating Lost and Misplaced Assets

With the mobile app and smart tags (QR codes, barcodes, NFC or BLE), every asset is uniquely identified and tracked in real time.

Employees can record check-outs, returns, and transfers anywhere using a simple mobile app, ensuring that each asset is accounted for.

Accurate digital records and clear chain of custody reduce asset losses, prevent duplicate purchases,

and ensure that tools and equipment are always where they should be.

Improving Employee Accountability

Every asset movement is logged with user, time, and location, creating a transparent audit trail.

Company employees know their responsibility for the assets they borrow or use, which discourages misuse or neglect.

Increased accountability ensures assets are returned on time and in good condition, reducing replacement and repair costs.

Streamlining Asset Tracking and Maintenance

Mobile forms designed for field work make it easy to record and

access service and maintenance data on the spot. Automated alerts ensure scheduled maintenance, calibrations, and inspections are never overlooked.

Field staff can instantly review equipment details and past service history on their mobile devices, helping them complete maintenance tasks faster and with

better results.

Together, these capabilities reduce equipment downtime, extend asset lifespan, and keep operations running without disruption.

Improving Asset Utilization

With the mobile asset tracking system managers can review real-time asset location and availability through a single web dashboard.

Real-time asset visibility allows managers to optimize deployment and ensure equipment is sent where it is most needed.

Analytical reports in the asset management system help managers make smarter purchasing decisions.

They can identify underutilized assets that can be used for projects, avoiding unnecessary purchases.

Mobile Asset Tracking Use Cases

Mobile asset tracking software is used across a wide range of industries to

improve efficiency, reduce costs, and enhance decision-making by providing real-time visibility into the location and status of valuable equipment.

Construction

- Tool and equipment management By using mobile asset tracking system for construction

contractors can track expensive tools and heavy machinery across multiple job sites with a QR code scanning mobile app.

Updates are instantly synced to the cloud, creating a clear digital asset audit trail.

The system reduces equipment misplacement, damage and loss, and ensures that critical equipment is available when and where needed.

- Equipment service and maintenance Mobile forms linked to the centralized cloud system create digital documentation of everything that was done

to the equipment: repairs, service, maintenance, inspections. The records include the service that was done, problem description and spare parts used for repairs.

This data, accessible on demand with a QR code scan, giv field technician info they need to perform the job fast and make informed decisions.

- Preventive maintenance Alerts built into the mobile asset tracking system ensure that preventive maintenance is done on schedule and is never missed.

By tracking the usage history of equipment, maintenance can be scheduled proactively rather than reactively,

minimizing costly downtime and extending assets lifespan.

2. Field Service

- Mobile tool tracking Field technicians can

track tools,

equipment and

spare parts on their

service trucks or

on the job site with QR code scan in the mobile app. Accurate service trucks asset tracking ensures that they have the correct

tools and parts for a job, and reduces repeat warehouse visits.

- Mobile data access Technicians can access equipment details: specs, documentation, service history with a single QR code scan in the mobile app.

This gives them info they need to do their job without wait and calls to the office.

- Fleet and vehicle tracking Businesses can monitor the location and condition of their service vehicles and trucks using GPS trackers.

This tracking optimizes routing, reduces fuel costs, and improves communication with drivers.

3. Manufacturing

- Work-in-progress (WIP) tracking

A mobile asset tracking system allows manufacturers to track orders through the production process

using smartphones and QR code scanning, and review status of everything in production on the

live status dashboard.

Real-time WIP tracking improves production efficiency and helps identify bottlenecks in the process.

- Inventory and tool control Manufacturing tools and inventory management on the shop floor using mobile devices and QR code / barcode scanning

improves visibility, reduces search time and prevents the loss of crucial equipment.

4. Healthcare

- Medical equipment tracking With accurate real-time mobile asset tracking hospital staff can locate critical medical equipment

fast, saving valuable time and improving patient care.

- Improved asset accountability Mobile equipment tracking creates digital chain of custody trail, improving staff accountability for equipment they use.

- Compliance and maintenance Tracking usage and maintenance history for medical devices helps hospitals stay compliant with strict regulations,

and ensures that equipment is properly sterilized and maintained.

Asset Management Challenges Solved With Mobile Tracking - FAQ

- How does a mobile asset tracking system work?

A mobile asset tracking system uses smartphones or tablets with a scanning app to read QR codes, barcodes, or BLE tags attached to assets.

Field and warehouse employees record assets transfer, check out, check in, assignments with a QR code scan in a mobile app.

Updates are instantly sent to a centralized cloud system, creating real-time asset visibility to all team members.

- What is the difference between asset tracking and inventory tracking?

Asset tracking focuses on managing serialized items such as tools, equipment, and machinery.

The system keeps track of asset location, usage and maintenance history.

Inventory tracking, on the other hand, monitors stock quantities of parts and materials to ensure proper supply levels.

QR Inventory supports both asset and inventory tracking in real-time, with mobile app and QR code scanning.

- What industries benefits from mobile asset tracking?

Mobile asset tracking benefits industries that rely on equipment and tools, that are often located at various field sites and frequently moved around.

These industries include construction, manufacturing, healthcare, utilities, and field services. Businesses gain better control, reduce losses,

and increase efficiency by giving field and office staff real-time access to asset data.

- Which asset tracking technology is best for my business?

The best technology depends on your needs. QR codes and barcodes are cost-effective and simple to deploy,

and allow for fast and efficient asset tracking with the mobile app. BLE and NFC tags are more advanced, and allow for faster mobile scanning.

Finally, for a fully automated asset tracking you can use IoT system, where IoT gateways track assets in designated locations in real time without a need for manual scans.

- Does a mobile asset tracking system require new hardware?

No special hardware is required. Your employees can use their existing smartphones or tablets with the mobile app.

Optional technologies like BLE beacons or IoT gateways can be added for automation if your business needs them.

- How does mobile asset tracking save money?

mobile asset tracking delivers significant cost savings by reducing lost and misplaced assets, eliminating duplicate purchases, preventing equipment downtime with timely maintenance,

and improving asset utilization.

- Does mobile asset tracking system integrate with other business software?

Yes. QR Inventory can integrate with ERP, accounting, project management, and other business systems via API, ensuring asset data flows

seamlessly between the systems without manual data entry.

- How easy is it to set up and use the system?

QR Inventory software has very easy to use interface and comprehensive contextual help. Our

AI / NLP tools make QR Inventory setup and daily use a breeze. Instead of trying

to find answer by sifting through instructions and manuals you simply ask your question in natural language using

our AI chatbot and get instant answer.

-

How does QR Inventory stand out for mobile asset tracking?

QR Inventory mobile app for asset tracking is optimized for fast and easy data recording with minimal manual entries, so that your employees

can complete the tasks fast. The app requires minimal typing thanks to smart auto-fill, scannable checklists, and QR/NFC/BLE scanning.

Unlike one-size-fits-all systems, QR Inventory adapts to your workflow and lets you customize your asset management process based on your specific use case.

The system is flexible - it supports a variety of smart tags and trackers so that you could choose cost-effective QR code scanning or a fully automated IoT system

that does not rely on company employees for asset management tasks.